Having a beer used to be a moment of pleasure that all consumers could afford. However, enjoying certain brands is becoming a real luxury. Since the beginning of the year and over the course of the summer, the consequences of sky-high inflation have already had an impact.

Beer is more expensive than in 2021, but let’s not kid ourselves, the inevitable effects of the rising prices for certain raw materials and other essential elements for brewing it, as well as supply chain costs, still haven’t hit us.

The rising costs of energy, glass, paper, and other raw materials like grain because of the war in Ukraine, are not making beer production easy. In this post, we explain how this increase is affecting the sector.

Ukraine, the granary of Europe and Russia, the owner of gas and other resources

The military confrontation over the “granary of Europe” that has resulted in shutdowns of exports from Ukraine, the fifth barley producer in the world, along with the sanctions on Russian aluminium imports (the other side of the conflict), are proving decisive in the manufacture of the increasingly expensive liquid.

While not all countries will suffer the same consequences, or at least in the same time frame (Spain, specifically, is self-sufficient in barley, so the effect will not be immediate), other devastating circumstances, such as the drought of recent months, will add to the problem.

Thermometers never dropped below 95-104 degrees over the summer, and this has meant that crops have not been able to grow normally. Therefore, a grain shortage is coming, whether we like it or not.

Other essentials in beer production

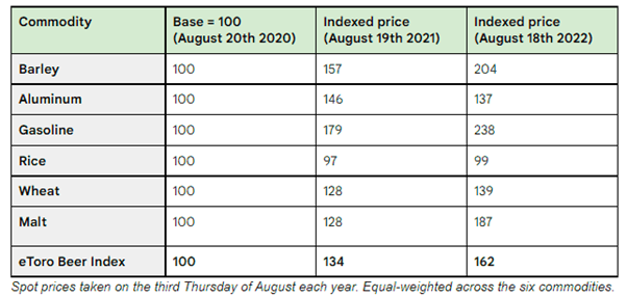

The cost of producing beer is approximately 62% higher now than two years ago according to the Beer Index, which was conducted by the eToro social investment platform. This analysis was based on the basic elements for producing beer: wheat, barley, rice, malt, aluminium and fuel.

1. Glass

Mini-bottles and regular bottles, two essential formats for beer, require glass. The energy surcharges due to the cut-off of the Russian supply (taking into account that glass requires 80% natural gas) have inevitably led the main suppliers of this material to raise their prices for their customers. Other glass suppliers like the United States and Algeria are also applying this increase.

2. What about aluminium?

We know that next to glass, aluminium cans are the containers for nearly half the beer consumed in Spain.

This material shook things up with a 100% price increase in early 2021, and the prices have only continued to rise since then. Other circumstances are adding to the problem, like sky-rocketing demand following the pandemic and the prohibition on buying aluminium from Russia, considering that it’s a leading producer, and the fact that energy prices are rising constantly.

3. Paper, cardboard and other inputs

The complicated situation with raw materials is also affecting the suppliers of paper and cardboard, a key product for beer packaging. If prices were already rising, the energy crisis has made them go up even more. This is a sector with very high energy consumption, one of the highest. Paper is responsible for no less than 5% of the world’s energy use.

And cardboard isn’t far behind. The demand for packaging for online purchases has led to a major shortage.

4. Transport and agriculture

Together with the energy crisis, we have the fuel crisis. We are very aware that fuel prices have been rising rapidly since the start of 2022. Growing and transporting grain for beer is now much costlier because it requires and depends on diesel fuel.

Increased gasoline prices inevitably have meant that truckers and farmers need to charge more for transport, increasing supply costs, which ultimately affects the final price of the product.

Comments