Let’s look at what gushing, or the sudden over foaming of beer is. What are the causes? What are the possible solutions? We answer all these questions in the following post.

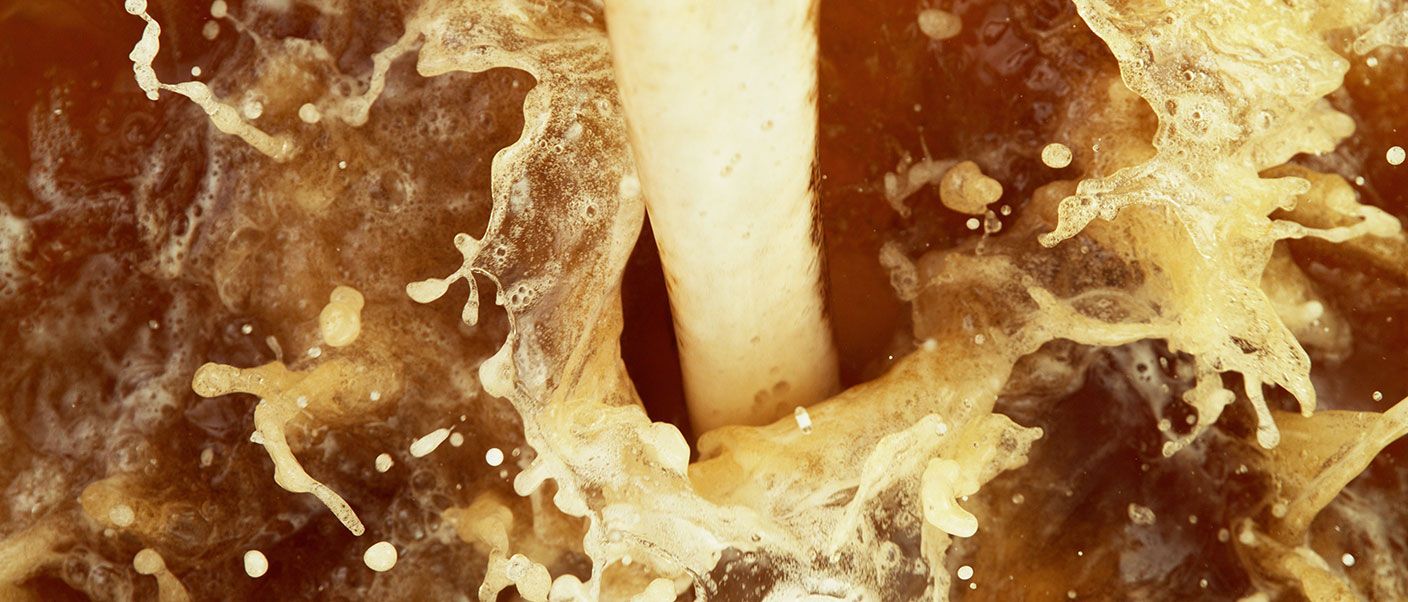

Gushing, or the unexpected overflowing that can occur upon opening a beer. It’s a phenomenon that happens more than it should and which the brewing industry has to wrestle with constantly.

Knowing or identifying the potential causes, as well as avoiding possible irregularities during the brewing process, will help keep it from happening and prevent defective products from reaching the end consumer.

The act of opening a beer that has not first been shaken in any way and suddenly overflows, spouting all its foam, losing half of this precious beverage, is something no beer-lover likes and which the craft sector fears in general.

Gushing procede del verbo inglés “gush” que significa “salir a borbotones”.

The dictionary defines “gushing” as “a sudden copious outflow”. In the beverage industry, and especially when it comes to carbonated drinks, we are very accustomed to hearing that onomatopoeic “fizz” sound when we open a container that contains a measured quantity of gas that is always just right.

However, in another class of beverages, such as craft beer, the carbonation is produced inside the fermentation tank during that process or inside the bottle itself.

Gushing can be of different magnitudes.

– As a violent outflow in which a large part of the content is lost

– As leakage from bubbling, in which a small quantity of liquid escapes

– In a more subtle way, as an excess of carbonation in the beer What’s more, gushing also refers to an excessive amount of gas in the bottle.

There are cases in which the bottle could even explode if it does not have specific qualities to support refermentation.

El gushing puede producirse en diferentes escalas.

Causes of gushing

There are different possible causes of gushing.

1. Excess carbonation

Firstly, and as one of the most common causes, high carbonation inside the bottle can cause the beer to generate excess foam that bubbles out of the bottle or can. Because too much CO2 is inadvertently concentrated during carbonation.

Also, when it comes time to do the “priming” (a term that is very well known in homebrewers’ jargon), that is, the process of adding a source of food for the yeast in the bottle, which can be of any type—sugar, honey, dextrose, etc.—which ensures that the yeast stays alive and carbonates naturally.

An error in calculating the quantities to be added can cause the phenomenon of gushing or even, under certain circumstances, overcarbonation with possible explosion of the bottles.

Therefore, and although here we are talking about processes in large quantities, in homebrewing it’s a good idea to avoid reusing bottles from major brewers because they are not designed for refermentation.

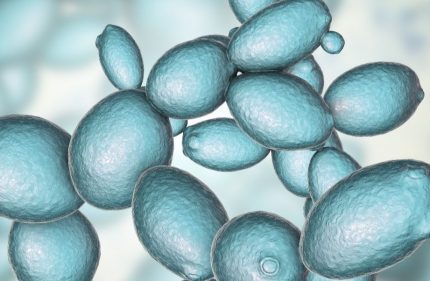

Another possible cause of gushing due to carbonation is contamination of the beer with a high attenuation micro-organism (for example, a wild yeast strain). The consequence is that the beer will continue developing inside the can or bottle and will not have the desired profile, presenting unpleasant flavours.

2. Fusarium Griminarium

That’s the name of a species of fungus that arises as a blight on numerous grains during pre-harvest rains or from storing them incorrectly in damp places.

If the malt used to brew the beer in question comes from barley or wheat infected with the fungus, it will contain proteins called hydrophobins which form microscopic capsules where the CO2 is retained under pressure. When the beer is opened, it is released and spills out in the form of foam.

3. Calcium oxalate

Also known as “beerstone”, it comes from the oxalate contained in the malt. In the presence of the calcium in the water during mashing, this material precipitates in the form of microcrystals, which give rise to gushing.

4. Mala higiene durante la producción y embalaje

Inadequate cleaning of the packaging that leaves traces of dirt or cleaning products can also cause the beer to overflow.

That’s why it’s essential to use new and totally hygienic containers.

5. Metal ions

Certain metal ions located in the diatomaceous earth used by breweries for filtration can cause gushing. Reducing the quantity of these metals as much as possible helps to prevent gushing and possible premature oxidation.

Solutions to gushing

With the development of brewing techniques and industrial production of beer, certain preventive control systems have been established to avoid possible overflow of the liquid.

Among other measures, and in the interest of stopping possible contamination (for example, due to the presence of Fusarium), the largest malting plants in the world use very advanced technologies that avoid defective malts.

And if excess calcium oxalate is produced, it is necessary to check that the quantity of minerals follows the processes during the brewing process and, if these crystals appear, to work to make them larger so that they precipitate and do not reach the can or bottle.

In short, a series of measures and solutions have been adopted to eliminate possible risks that could alter the product.

Comments