FERMENTATION AND CONDITIONING

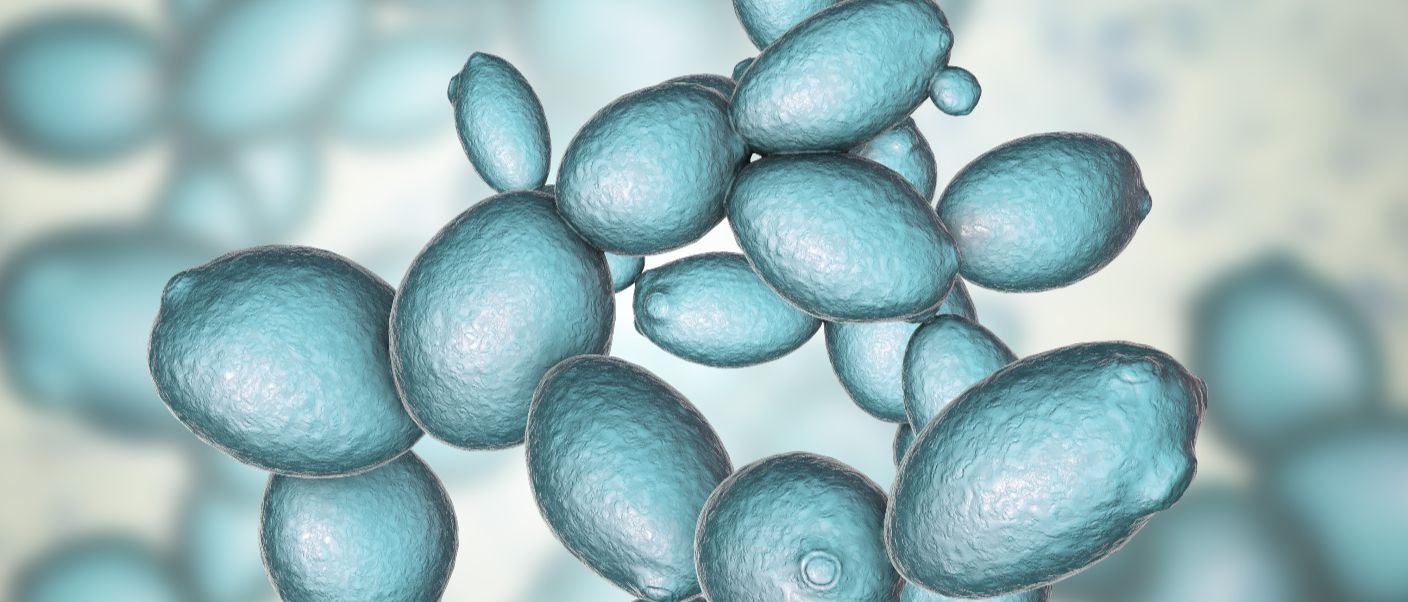

The addition of yeast is the moment of greatest risk in terms of contamination, given that each undesired micro-organism will multiply at its own pace, likely giving its own personality to the beer.

For that reason, a good yeast conservation protocol will avoid cross contamination between the yeast and bacteria in the environment.

Therefore, compliance with a strict protocol for yeast addition and cleaning and disinfection of fermenters, hoses and pipes will be the way to avoid undesired aromas in your final beer. Furthermore, if the yeast is recovered from another tank, washing the yeast with acid at 2.8 pH is a good solution for ensuring that the culture is free of other agents.

Always working with the quantity of cells necessary according to the yeast’s technical sheet will also stop other party crashers or, at least, keep them from having much space to develop.

A bacterial concentration of 10E4/ml will completely cloud the beer, and it won’t be difficult to find flavours of phenols, cheeses, sulphur, butter or solvent, among others.

When wild yeasts are used, the most likely possibility is that they will produce phenolic and medicinal aromas—as well as much higher attenuation than expected—if our travelling companion is the S. Diastaticus yeast. A good system of yeast propagation with sterile air and regular checks will minimise this risk.

Contamination with Zymomonas in this part of the process will make the yeast flocculate before having finished its fermentation, although this is not common.

These types of contamination will occur throughout the entire fermenter.

BOTTLING

Any of these situations mentioned above can arise in the period from cooling to bottling. Therefore, it is necessary to check each of these points to locate the site of the problem and solve it. If a problem is found in the cooler, it does not mean that it this the only problem; after solving it, it will be necessary to continue checking until the end to determine if it was the only site.

In products with a pH of greater than 3.5—almost all beers except sour ones—another risk is contamination with zymomonas mobilis, which, if it occurs during bottling, can recur in a pattern of every x bottles or cans, if located in the filling nozzles, or variably, if it occurs in any other area or point in the bottling process.

These beers will have a sulphurous aroma, similar to burnt matches, rotten eggs or sewers.

Comments