There are various alternatives for obtaining a beer with little or no gluten.

Selection of Gluten-Free raw ingredients

Among the raw ingredients we are going to use to make beer, we need to consider the grains, as these are what have the potential to supply this allergen.

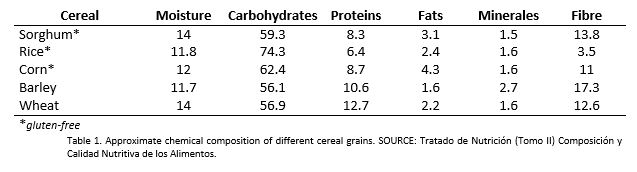

The gluten-free cereals currently used the most are sorghum, rice and corn. To brew beer using a cereal other than barley, we have to know the differences between the grains.

For example, if we choose sorghum, the differences with respect to barley are the following:

- The composition of the grain is different (table expressed in %).

-

- Sorghum does not have a hull.

- The generation and activation of enzymes during the malting phase affects different areas of the grain.

- The endosperm of malted sorghum maintains compaction of the starch and does not disintegrate as in the case of barley malt.

- Malted sorghum contains low levels of endo-ß-glucanase and ß-amylase.

- The losses from malting (respiration and root-sprouting) are around 20% in sorghum and 7% in barley after 6 days of growth at 25ºC.

The malted versions of gluten-free grain are not typically available on the market, and the necessary enzyme complex must be malted and/or implemented externally for correct mashing.

Due to the physiological differences between grains, each one must be malted in a particular way.

Continuing with sorghum, it has been demonstrated that the diastatic power of its malt and the level of free amino nitrogen (FAN) are enhanced at a soaking (up to 32% moisture) and germination temperature of 30ºC (higher than that of barley), and also with a particular concentration of the alkaline solution (0.1% up to 0.5%), as this favours the activity of the ß-amylase.

In the drying of sorghum malt, it has been demonstrated that good results are obtained with a process involving two phases of 55ºC and 65ºC.

During mashing, the modification of the grain during malting must be taken into account, because if this is not very good, the best option is probably to apply enzymes externally to favour the mashing process.

Additionally, the gelatinization temperature of sorghum is higher than that of malt and corn, which can pose problems of viscosity and reduced production of reducing sugars and FAN.

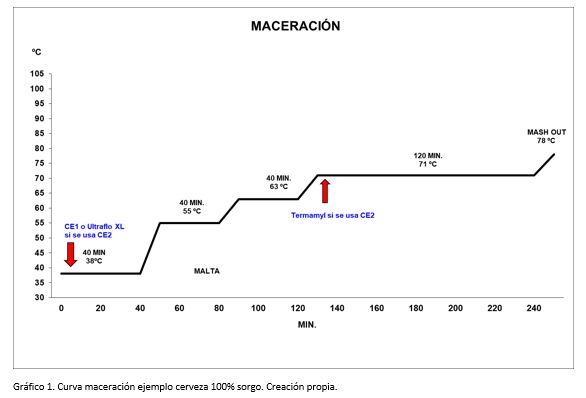

Use of the following enzymes is recommended:

- α-amylase: to ensure saccharification.

- ß-glucanase: to favour filtration to reduce viscosity.

- Glucoamylase: if the idea is to make glucose syrup with starch-water to add as an extract in the recipe.

Examples of enzymes that could be used:

- Enzyme complex 1 (EC1)

- Brewers CompassTM contains α-amylase from Bacillus amyloliquefaciens and Bacillus licheniformis, endo-1,4-ß-glucanase from Trichoderma longibrachiatum and endopeptidase from amyloliquefaciens. At a concentration of 1.5 kg/t malt.

- Enzyme complex 2 (EC2):

- Termamyl 120 contains α-amylase from licheniformis. Use accompanied by Ultraflo XL. At a concentration of 0.5 kg/t malt.

- Ultraflo XL contains ß-glucanase from Bacillus subtilis. Use accompanied by Termamyl. 0.2 kg/t malt.

- ABV glucoamylase 400 contains amyloglucosidase from Aspergillus niger. At a concentration of 1.5 kg/t malt.

An example of mashing for a 100% sorghum beer might be:

We also must take into account whether the grain selected for brewing has a hull, because if it does not, rice hulls can be added to help filter the wort.

Filtering, boiling and fermentation would be similar to that of a gluten-containing beer; the only recommendation is to add some type of nutrient to enhance fermentation.

Use of chemical additives or pantented techniques

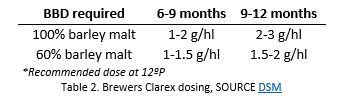

Brewers Clarex, a proline-specific endopeptidase (entoprotease) obtained from A. niger can be used to break down the “toxic” segments of the gluten. It is added at the start of fermentation in the following doses.

This is also a stabilizer that recognizes the proteins responsible for chill haze.

Although, it should be noted that the results are better if accompanied by a beer brewing process designed to reduce the protein content (vigorous boiling of the wort, long mashing time at a low temperature and filtration of the beer).

Some brewers use silica gel (SG) during fermentation. This makes it possible to further reduce the gluten without significantly changing the nutritional value of the yeast in the beer. Furthermore, it promotes the reduction of polysaccharides, improving filtration.

New techniques

Hydrodynamic cavitation (HDC) is a physical process that is very similar to boiling; the difference is that cavitation is caused by a drop in the pressure of the fluid below the vapour pressure, whilst boiling accomplishes the same thing above the local ambient pressure.

It has been demonstrated that hydrodynamic cavitation is effective both during mashing and at the start of fermentation. The pressures achieved in this process alter protein complexes (like proline), and the formation of oxygen in the fermentation mixture enables the enzymes and yeasts to break down the proline.

Supporting this idea is the discovery that proline displays high assimilation by certain strains of yeast, particularly under high-stress conditions due to the dearth of the most easily assimilated amino acids.

Comments