Before getting into the topic, we have to start out by talking about the quality of a product, as food quality and safety are inseparably related.

Quality and quality-related costs

There are many definitions of quality, but if we want a concise one, we can say that:

“Quality is the match between what is desired and what is obtained”

This definition characterizes quality as something subjective, and, in a way, although a product may have great quality in technical terms, if it is not what the consumer expects or poor conservation has caused it to deteriorate, the result is that the consumer does not perceive the product as having the expected quality.

Evidently, giving a product quality has associated costs, but below we’ll see that they are worth it.

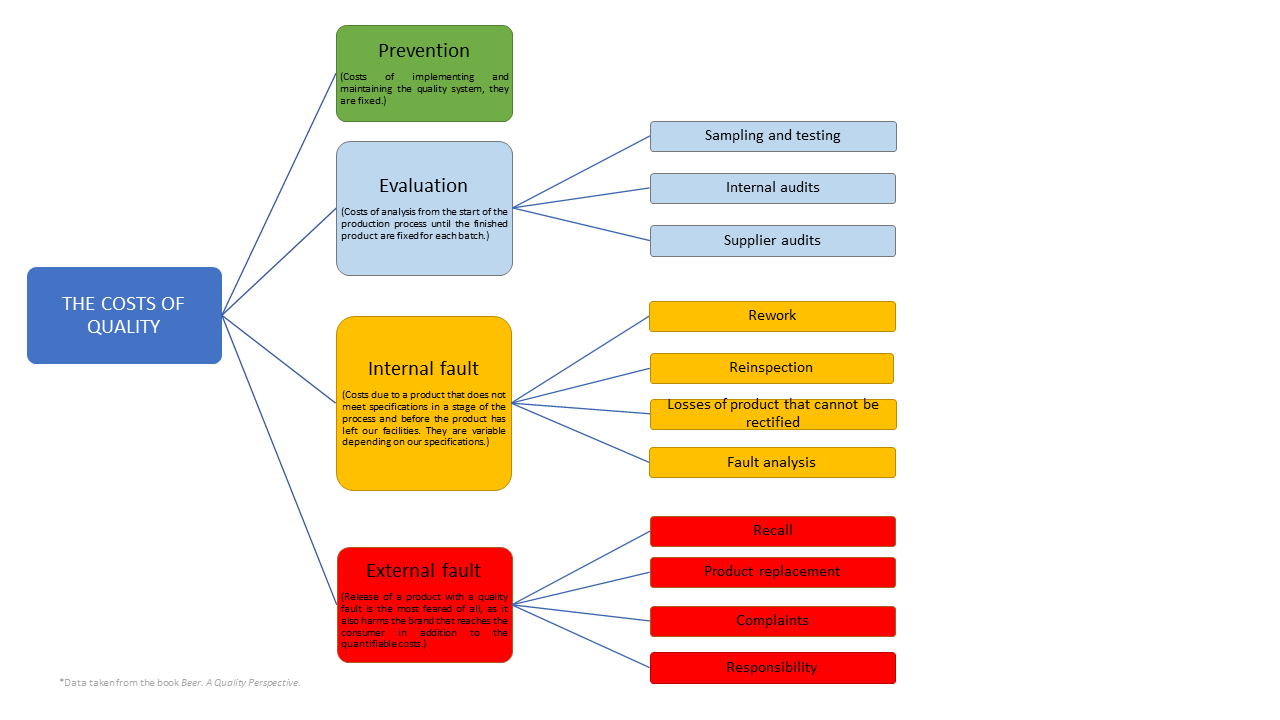

The costs related to quality can be grouped in:

What is Food Safety?

Food safety encompasses a set of legal standards that regulate the food industry, and it has two main purposes:

- Protect consumers’ health by establishing legal obligations regarding hygiene and safety practices in the food industry.

- Protect consumers from fraud, adulterations, etc. but without diminishing product quality.

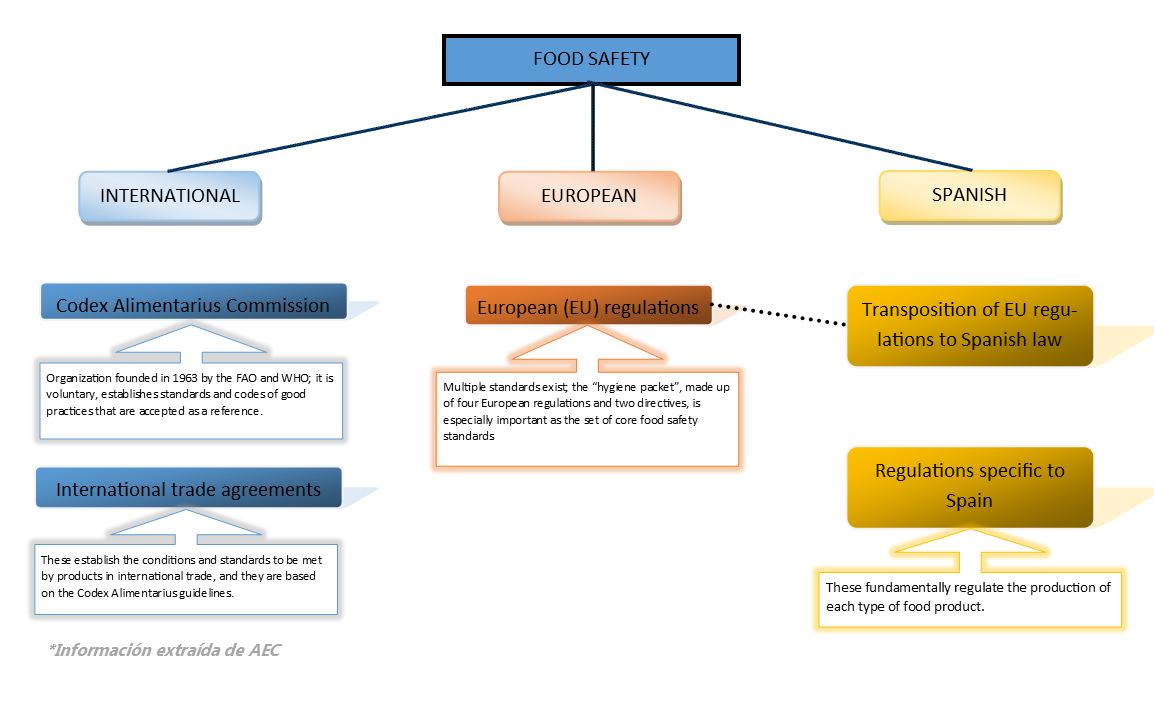

Food safety laws have different sources and different areas of application:

Why ensure food safety?

Food safety is a point of concern for any food company that wants to endure over time, not just because of the penalties that may be applied but also for the negative impact an incident can have on a company or a sector.

For example, the health crisis due to listeriosis in shredded beef that occurred in Andalusia in 2019, resulted in a 60% drop in shredded beef sales according to ANICE.

Or how the cucumber crisis caused by E. coli, which occurred in Germany in 2011, left two Spanish companies on the verge of bankruptcy and affected the entire Spanish agricultural sector.

And, what is a food risk?

For any food, the potential risks are the following:

- That the components of the raw materials are toxic.

- Contaminants associated with the raw materials.

- Microbial infections.

- Contamination related to transport, distribution, storage and packaging.

- Contamination that occurs during processing.

- Contamination associated with additives, adjuvants or materials that come into contact with the product.

- Deliberate contamination of the food.

- Presence of allergens.

With contamination understood to mean as any physical, chemical or organic factor outside the product. For example, a shard of glass (physical), traces of soap (chemical) or mould in milk (organic).

Therefore, any company that sells a product for human consumption must ensure that these points are covered to avoid a food incident.

And with beer?

Beer is not free of food risks, although, given its circumstances, it is a product that is quite safe microbiologically in terms of food safety, as there are no known pathogens that can proliferate in beer due to the conditions created by the alcohol, CO2, pH and hops. But that doesn’t means that we don’t have to worry about quality or food safety, as we can find ourselves having to carry out the feared product recall, for example, due to overpressure in the bottle due to refermentation, which happened to Lakefront Brewery and Ballistic Beer.

If you want to learn more about beer spoilage, you can read Beer Spoilage Bacteria and Hop Resistance, Probrewer.

Some other examples of beer recalls are:

Furthermore, the craft beer trend of using use new ingredients to innovate and differentiate the product in the market introduces allergens, bacteria, yeasts and contaminants into the beer world that we are not accustomed to dealing with and which may be legally regulated—such as pulegone in mint, lindane in cacao or perchlorates in coffee. We need to take this into consideration when launching a new product.

Other contaminants such as heavy metal, nitrosamines, mycotoxins, pesticides, pests, etc. must also be watched.

Therefore, food safety is not just for large brewers; small brewers must also keep it in mind for legal compliance and to avoid brand deterioration and economic losses.

How can we control health risks?

As seen with health risks, they can be present from the raw materials to consumption of the product, and therefore must take a series of measures to ensure product safety.

For raw materials, we must ensure that they comply with current legislation, know what allergens they contain, and request and read their technical specifications. A common measure is to agree on quality with suppliers.

At the company level, there are multiple management systems and protocols to guarantee product quality, such as, Food defense, ISO systems , GMP, FSSC, AIB, IFS.

All these systems or protocols are based on an HACCP and a system of traceability.

What is an HACCP?

It’s an acronym that stands for Hazard Analysis and Critical Control Points and which seeks to determine all the points where a food risk might be present and apply measures to prevent or monitor them so that they can be detected early if the risk materializes. Their use today has been extended to cover parameters related to product and process quality as well.

In 1993, the European Commission published Directive 93/43/EEC concerning the hygiene of food products, establishing the obligation to implement HACCP systems for the European food industry as a whole.

The main HACCPs established by the FAO and WHO are the following:

- Principle 1. Conduct a hazard analysis. Considering the entire process, from raw materials to transport of the finished product.

- Principle 2. Determine the critical control points (CCPs). The hazards are assessed according to their impact and probability, generating the CCPs.

- Principle 3. Establish critical limits beyond which the product is not suitable.

- Principle 4. Establish monitoring procedures (Monitoring Plan).

- Principle 5. Establish corrective actions.

- Principle 6. Establish verification procedures.

- Principle 7. Establish record-keeping and documentation procedures.

In order to implement an HACCP, a set of pre-requisites must be fulfilled first.

What is the monitoring plan?

It is the series of measurements, checks and chemical, microbiological or physical analyses that we undertake during the process to cover the critical points. It should clearly state what is being looked for, where, how, limits and action, if necessary.

They are typically expanded with controls related to the quality of the product to ensure quality during the entire process, which enables us to obtain preventive quality.

What is quality assurance?

Traditionally, manufacturers have used the quality control methodology, which is a reactive approach, as it seeks to detect the presence of quality defects in the product. The product is considered invalid if any are found, which generates economic losses for us that can be considerable depending on which batch is affected.

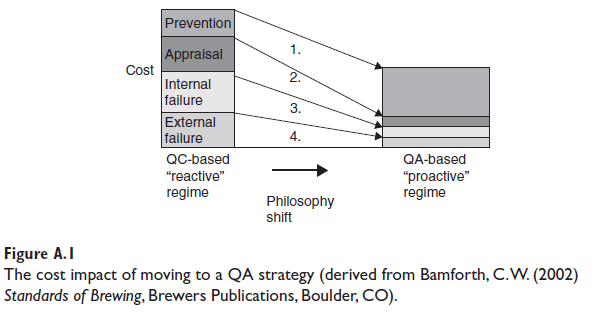

Much more efficient is the quality assurance approach, in which systems are introduced that are designed to assure that the product meets specifications in each of its production stages. We can say that the difference between the two approaches is that quality assurance prevents problems instead of detecting them, as opposed to the quality control approach.

The graphic illustrates that greater investment in prevention enables us to reduce evaluation costs, but, much more importantly, it enables us to greatly reduce the costs related to internal and external faults.

In conclusion

To summarize, although quality and implementation of an HAPCC has associated costs that at first glance do not appear to be recovered, the HAPCC helps us implement a quality assurance approach that will give us economic benefits over the long term and create a good name for the company.

If you want to learn more about best hygiene and monitoring practices in breweries, you can visit these sites; Guía de la Generalitat, BOE – Código cerveza; Guía de Cerveceros España.

Literature consulted

- Beer: A Quality Perspective.

- Spanish Quality Association (AEC) — https://www.aec.es/

- Codex alimentarius — web

- Quality, Safety and Nutritional Aspects. HUGHES and BAXTER

Comments