The general concern about climate change that has existed for years and the actions for addressing emissions and greenhouse gases are causing major brands to include a series of sustainable services and actions aimed at caring for the environment in their portfolios.

In the crosshairs of the consumer and as the most important goal within the beverage industry, we find initiatives as important as waste reduction and recycling chains and sustainable packaging programmes, together with other measurement aspects which we are going to focus on in this new post: an analysis of the lifecycle and reduction of the carbon footprint of products.

Find out what types of actions are being taken in the sector and what they involve.

Carbon footprints, the key to measuring gas emissions

The fact of the matter is that the beverage industry contributes significantly to carbon emissions. And so carbon footprints have emerged as a key element and a piece of unfinished business within most companies’ environmental management and commitment.

Carbon footprint calculations measure emissions or the amount of CO2, both in production of the raw materials and the packaging process.

They are also used in production operations, transport between a company’s own plants and warehouses, in the retail part, and even in recycling, once the products are finally consumed.

The numerical value or percentage is calculated by estimating the amount of greenhouse gases generated both directly and indirectly (for example, the amount of electricity consumed in the operation of equipment).

Reducing the impact of a carbon footprint without renouncing constant growth and the normal pace of production, is a prime objective.

For that reason, companies are implementing plans aimed at reducing their environmental footprint significantly.

The risk of emissions in beverage production

The highest gas emissions in the manufacture of beverages are found in other processes in:

- Raw materials selection: by means of adequate selection, at the crop level, and substitution of environmentally-friendly materials.

- Bottling: the bottling chain and the use of raw materials in containers such as non-biodegradable plastic and polluting cans.

That’s why they’re looking for new formulas and sustainable, environmentally friendly materials.

- Packaging: this is another of the processes that produces a large carbon footprint.

Most factories are currently designing and implementing improvement plans to reduce their environmental impact by increasing the amount of materials for recycled and recyclable packaging.

- The cold chain: Beverage cooling accounts for a very high percentage of a carbon footprint (around 27%, for example, in the case of Heineken Spain).

Goal: maximum reduction of their carbon footprint

There are numerous cases of beverage companies that, in order to achieve the maximum reduction in their carbon footprint, have established a firm commitment.

Given the actions of its own lobby, the gigantic Coca-Cola Company cannot skip these types of initiatives. Its strategy sets a deadline of 2025 and consists, among other actions, of working on sustainable farming of the key ingredients in its products to achieve a 25% reduction in its footprint by 2010.

The Starbucks chain, among other international projects, has already done so with the intention of eliminating plastics by redesigning their cups.

A container that can be reused up to 100 times with a very small carbon footprint.

Among its other successful projects is the “Cup-Share Program”, which consists of customers using a cup and returning it to the store with a one-dollar-deposit.

Mahou San Miguel, a leader with its plan for reducing its carbon footprint

To calculate its carbon footprint for the period between 2013 and 2020, Mahou San Miguel took into account:

- As a significant gas, the carbon dioxide emissions from the combustion furnaces used to produce heat.

- Greenhouse gases from heating and air-conditioning equipment.

- Indirect emissions from electricity (especially in production centres and administrative offices).

It does not include gases from the fermentation process or the combustion of biogas generated in the waste water treatment process, as they stem from renewable biomass and have a neutral effect.

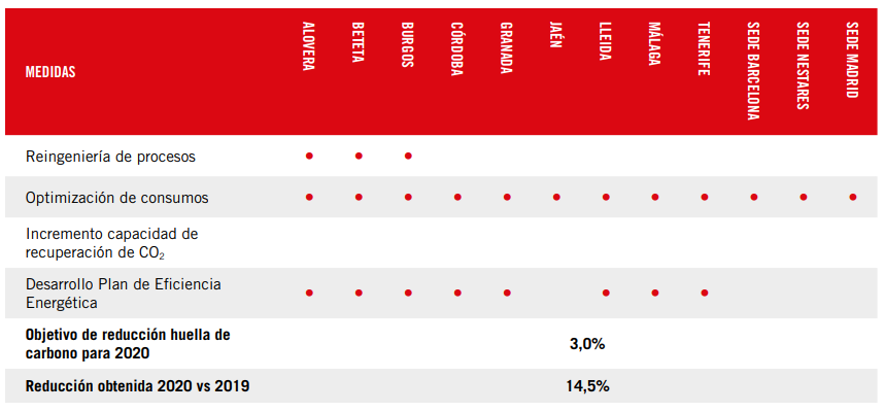

Based on its commitment and looking back at 2020, Mahou San Miguel experienced a significant emissions reduction that was much greater than expected.

In addition to the circumstances related to the pandemic, which triggered an inevitable drop in industrial activity, in 2021 the following data were recorded for facilities, and the company established a reduction commitment of 4.5%:

Lifecycles. What do they involve?

Another great challenge facing the industry is related to lifecycles.

A lifecycle is a process that makes it possible to evaluate, in general terms, the environmental impact associated with a specific product, from extraction of the raw materials to its disposal following consumption.

The process is capable of calculating up to 12 specific carbon footprints. Among its advantages:

- It identifies opportunities for improving the environmental performance of the product in the design and development phase.

- By comparing products to enable selection of more sustainable alternatives.

- Other advantages such as the order of priorities in the strategic planning of the product or even undertaking ecological marketing strategies.

Sustainability in manufacturing and production systems is something that is part of the DNA of Brew&Hub. From the outset, we have been highly committed to measures aimed at respectful and responsible manufacturing, and so our portfolio of services includes the carbon footprints as an essential ingredient in the supply chain.

Comments